The engine is the vehicle’s driving power source. It converts fuel energy (input) into torque (output). Power is defined as the product of torque multiplied by the engine’s rotational speed.

Power [kilowatts] = engine torque [newton meters] x rotational speed [circular angle per second]

The torque engine depends on the energy generated by the combustion of the fuel-air mixture, and the higher the torque, the greater the engine’s power. The value of the torque is affected by the value of the force acting on the piston multiplied by the torque arm.

Engine torque [newton meters] = force [newtons] x torque arm [m]

= (charge pressure x piston area) x torque arm.

The engine power can be increased by:

– increasing the engine torque or

– reducing the loss in power as a result of friction inside the engine, or as a result of the operation of the engine accessories.

Methods of increasing engine torque:

Torque is the product of the force in its arm, the greater the force transmitted from the piston to the connecting rod, the greater the torque, and the greater the power arm (the length of the crank shaft throw), and the torque can be increased as follows:

1- Increasing the amount of charge inside the engine. (Engine Capacity x Volume Efficiency)

2- Increasing the thermal efficiency (combustion efficiency) of the charge and making use of some of the energy lost with the exhaust gases.

3- Increase the length of the elbow to the crankshaft.

4- Reducing the wasted energy in friction, as well as the energy expended to operate the internal and external engine accessories (increasing mechanical efficiency).

Volumetric efficiency determines the amount of charge entering the cylinder (engine). Thermal efficiency determines the amount of thermal energy that can be extracted from the energy contained in the fuel entering the engine by the charge. The mechanical efficiency determines the value of the remaining energy (power) as the engine’s output, as the energy extracted from the fuel is wasted part of it as a result of friction of the moving parts inside the engine and part is made to operate the internal and external engine accessories.

1- Increasing the charge inside the engine The

amount of charge increases with the increase in the engine swept volume, and the engine capacity is known as the cylinder capacity multiplied by the number of cylinders. The cylinder capacity is the area of the cylinder multiplied by the stroke length (the distance between the upper dead point and the lower dead point).

Engine capacity [cc, or liters] = number of cylinders x cylinder capacity [cm3, or liters]

= Number of cylinders x (cylinder area x stroke length)

= Number of cylinders x (t/4 x square cylinder diameter x stroke length)

1- (a)- Increasing the engine capacity by:

Increasing the number of cylinders (6, 8, 10… ..)

· increase the cylinder dimensions (diameter, length of half)

volumetric efficiency:

but it should be noted that despite the proven engine capacity of the torque varies depending on the speed of rotation of the engine due to the change in volumetric efficiency ( the degree of filling cylinders with a mixture of fuel and air). The volumetric efficiency (fullness efficiency) is known as Volumetric Efficiency; It is the ratio between the volume of the charge entering the engine to the engine capacity, or the volume of the charge entering the cylinder to the cylinder capacity, which is usually in the range of 80% to 90%.

Volumetric efficiency (fill efficiency) = actual volume of air (charge) entering the cylinder (engine) ÷ cylinder volume (engine)

The filling efficiency depends on the throttle opening, engine rotational speed, shape and dimensions of the intake and exhaust manifold, valve opening size, valve timing, and period Open the valves.

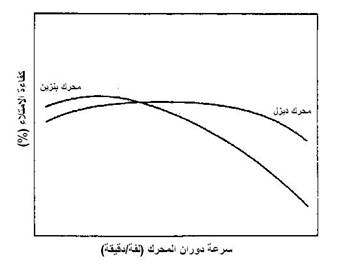

At slow speeds, the piston speed is slow, and the vacuum inside the cylinders and the intake manifold is small. Therefore, the amount of mixture entering the cylinders is small, and the filling efficiency is low. With increasing speed, the amount of fuel entering the cylinders increases, and the filling efficiency increases with increasing speed.

However, as the engine speed continues to increase, the mixture scrambling to pass through the valve openings reduces the amount of fuel entering the cylinders (this is called throttling and the engine not being able to breathe), so at higher speeds the efficiency of filling decreases.

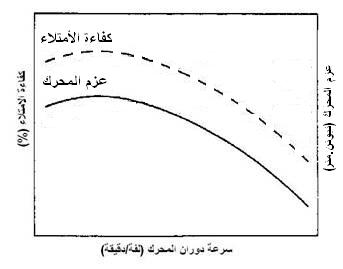

The relationship between volumetric efficiency (filling efficiency) and engine torque: the

higher the degree of filling, the greater the engine torque, and for this we find that the torque curve with respect to the rotational speed of the engine is similar to the filling efficiency curve. At slow rotational speeds, the filling efficiency is low, and accordingly, the torque is low. With the increase in speed, the filling efficiency increases and the torque increases, and at the speed at which the filling efficiency is maximum, then the maximum torque is then, and with the increase in speed more than that, the degree of filling decreases due to the throttling of the incoming charge and the torque decreases by extension.

1 (B) – Increasing the volumetric efficiency (Volumetric Efficiency VE):

* Increasing the number of valves, using 4 to 6 valves per cylinder. (Increasing the number of valves instead of using a large valve is to reduce valve mass that has problems when over speeding, over acceleration and deceleration)

* Variable Valve Timing with Intelligent (VVT-i) Electronically controlling intake valve timing

Variable Valve Timing & Lift with Intelligent (VVTL -i) * Electronically control valve opening timing and distance

Variable Length Intake Manifold (VLIM) * Use of variable length intake manifold

* Use of sleeve valve

* , turbo and super charging system Engine charging. Recharging the motor increases the fill efficiency by 50%.

* Getting rid of exhaust residues in the cylinder. By increasing the number of exhaust valves, controlling the exhaust valve timing in addition to the Dual VVT-i intake valve timing, creating two exhaust pipes for each cylinder headers (the idea behind using one exhaust pipe for each cylinder is to reduce the back pressure in the exhaust system which hinders exhaust exhaust more efficiently ).

Thermal efficiency:

Since the volumetric efficiency (filling efficiency) decides the amount of charge entering the cylinders, the thermal efficiency decides how much of the fuel energy entering with the charge can be converted into useful energy.

Thermal efficiency = energy used from the fuel ÷ energy contained in the fuel.

The energy used from the fuel can be increased by:

a- improving combustion, increasing the combustion efficiency (Thermal Efficiency TE)

b- reducing thermal energy loss, (loss in thermal energy) , cooling water 30-35%, exhaust gases 35-45%), friction inside the engine 5-8% in addition to the energy needed to operate the engine accessories)

2- (a) Increasing the combustion efficiency (thermal efficiency):

– increasing the compression ratio

Compression ratio = space above the piston at the lower dead point ÷ volume over the piston at the upper dead point.

Increasing the compression ratio leads to an increase in fuel efficiency and power. The compression ratio of gasoline engines is in the range of 8 to 1:9, and diesel engines are in the range of 17 to 19:1.

– The use of electronic fuel injection (EFI)

– The use of electronic ignition

– engine design and modifications, to increase the process of excitement inside the engine, and increase the degree of mixing, and this is done by designing the combustion chamber and the intake manifold.

2- (B) Utilizing some of the energy lost with the exhaust gases:

– Using the Atkinson cycle instead of the Otto cycle, where the expansion ratio is greater than the compression ratio of the engine.

3- Increasing the length of the elbow for the crankshaft:

– This depends on the design of the crankshaft, the greater the length of the elbow, the greater the stresses on the shaft.

Mechanical Efficiency: Mechanical efficiency is

defined as the amount of power out of the engine relative to the power generated from the heat energy generated inside the cylinders.

Mechanical efficiency = power out of the engine (braking power) ÷ power generated inside the cylinders (graphic power)

4- Reducing torque loss (Increasing Mechanical Efficiency ME):

The power loss can be reduced as a result of friction inside the engine or due to the operation of internal parts or External accessories mounted on the engine:

A- Modified design of the engine parts

B- Reducing the wasted energy for running the engine accessories.

A- A modified design of the engine parts to reduce the loss in friction:

– Using an engine with a bore/stroke ratio greater than one, which is called an oversquare engine, which has a diameter greater than the stroke. This leads to a reduction in the length of the stroke while maintaining the capacity of the cylinder, and accordingly reduces the amount of energy lost in friction.

Coating the cylinders from the inside with a material that reduces friction.

( B ) reduce energy (power) lost for the operation of the engine Mahlqat internal and

external:

-alastgina for camshaft in the engine camless valvetrain, where about 25% of the engine ‘s ability to lose speed in the empty pregnancy as a result of the forces exerted to open the valves against the spring.

– Using an electric cooling fan (instead of a mechanical fan that takes movement through the crankshaft)

– Using an electric servo for steering (instead of a hydraulic servo that takes its movement through the crankshaft)

– Using a servo (Power Mister brake) (instead of a hydraulic servo that takes its movement through the crankshaft) It takes its motion via the crankshaft). Or use a vacuum servo.

The factors affecting the engine’s power can be summarized by the following equation, and

in the event of a desire to increase the engine’s power, this is done by increasing the value of the limits of that equation:

Engine power = (the amount of power coming out of the engine) ÷ unit time

= ((the amount of power coming out of the cylinders) x mechanical efficiency) ÷ unit time

= (((the amount of energy contained in the fuel inside the charge) x thermal efficiency) x mechanical efficiency) ÷ Unit of time

= ((((engine capacity x volumetric efficiency) x calorific value of fuel) x thermal efficiency) x mechanical efficiency) ÷ unit time

Engine power can be increased by:

– Increasing engine capacity

– Increasing the volumetric efficiency of the engine

– Using valuable fuel High thermal

– Increasing the thermal efficiency of the engine

– Increasing the mechanical efficiency of the engine

There are no reviews yet. Be the first one to write one.