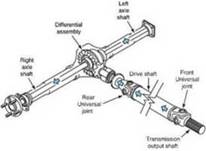

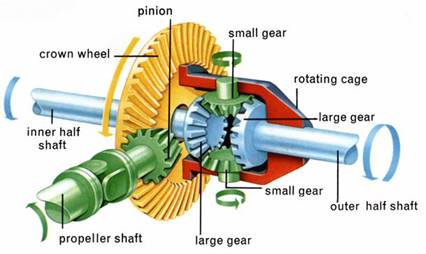

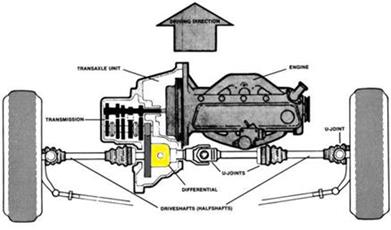

the differential gearbox (increasing torque – reducing speed, and transferring torque to the wheels). Working theory, parts, types:

Differential function:

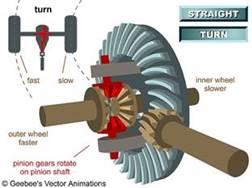

- Allow a difference in the speed of the driving wheels (the speed of the inner wheel, the speed of the outer wheel in the curve) when the car enters a curve.

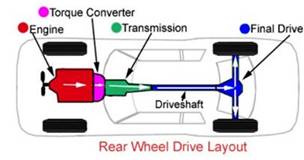

- The direction of transmission shifted from the longitudinal direction of the vehicle (from the gearbox to the rear axle) to the transverse (wheel axle) direction “for front-engine and rear-wheel drive FR vehicles”.

|  |

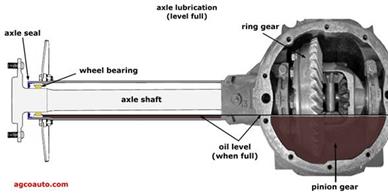

- The differential provides a reduction ratio of speed and double the torque (via the ring gear and the pinion of the propeller shaft) which is called the drive-axle ratio, final drive ratio, rear-axle reduction ratio axle ratio, and sometimes the back-axle ratio or front-axle ratio.

The final reduction ratio (if) = the number of teeth of the ring gear / the number of teeth of the pinion gear,

which reduces the weight and size of gears and gearbox components, and does not increase the torque transmitted from the gearbox, and therefore a transmission shaft with less diameter and weight can be used.

The total reduction ratio of the car is it = ig x if (where it is the total reduction ratio, ig the reduction ratio of the gearbox gearboxes “variable ig1, ig2, ….etc.”, if the final reduction ratio )

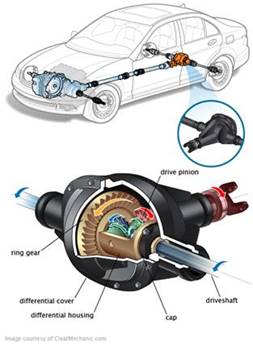

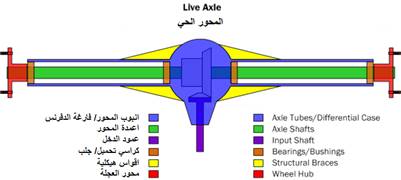

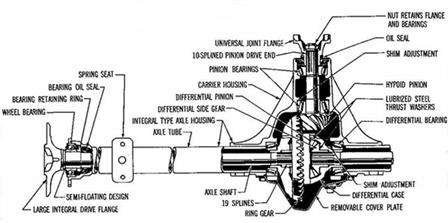

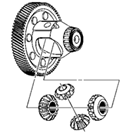

Parts and components of a differential gearbox: The differential

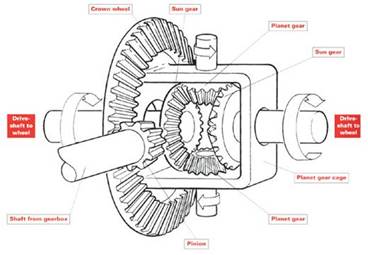

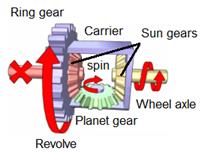

gearbox is a gear train set with three shafts, the input shaft with a pinion, and the two shafts of the wheel axle with a wheel hub at their end. The ring/crown gear is engaged with the pinion gear mounted on the input/drive shaft. The ring gear is mounted on the carrier with a set of gears (2 planet gears “spin with the carrier” around 2 solar gears, each one of them connected to the shaft of the wheel).

|

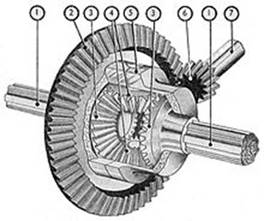

| Motion and torque are delivered to the differential gearbox from the gearbox by means of a small bevel gear (6) connected to the shaft (7), and engaged with the drive gear (crown gear) (2) mounted on the carrier (5) which Compound with 4 bevel gears (4) engaged with bevel gears driven (3) mounted to axles (1). |

Working differentials in a car:

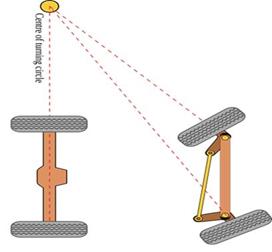

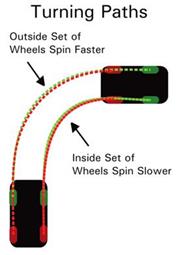

In cars and other wheeled vehicles, the differential allows the outer wheel to spin faster than the inner wheel during a bend. The set of the angular velocity of the two wheels is equal to the speed of rotation of the input shaft (drive shaft). Increasing the speed of one wheel is counterbalanced by decreasing the rotational speed of the other wheel.

The differential gear connects the input shaft to the pinion gear, which in turn turns the crown wheel of the differential.

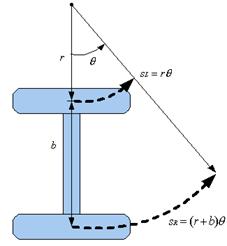

Differential gears are designed to drive a pair of wheels while allowing them to rotate at different speeds. When entering a bend, the inner wheel travels a shorter distance than the outer wheel.

| Functional description . work theory | |

|  |

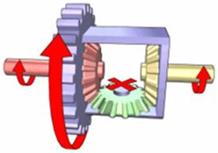

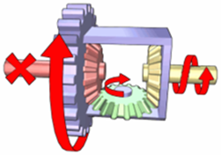

| The movement of the car in a straight line, the internal torque, affects the “blue” ring gear, which drives the “blue” carrier. The mount communicates with both “red and yellow” sun gears only through the “green” planet gear. The torque and movement are transmitted to the solar gears through the planetary gear fixed to the holder. The two planetary gears rotate with the holder around the axis of the holder, and they rotate the solar gears with them. If there is equal resistance to the two wheels, the planetary gear will rotate without spinning on its axis, and the wheels of the car will rotate at the same speed. | In the event that the “red” left sun gear encounters resistance, the “green” planetary gear will spin as well as revolve, allowing the red sun gear to decelerate, with equal velocity acceleration into the “yellow” right sun gear. |

|

The gearbox always works on:

1- Dividing the torque equally between the two wheels.

2- Make the average speed of the inner and outer wheels equal to the speed of the ring gear.

Nc = (Ni + No) /2 …….(1)

Thus

No = (Nc x2) – Ni

Ni = (Nc x 2) – No

where:

Nc = speed of rotation of the crown gear (rpm)

Ni = speed of rotation of the wheel Internal (rpm)

No = Outer wheel rotational speed (rpm) The

speed of rotation of the crown gear is always equal to the average speed of the sum of the shafts. In the case of a decrease in the speed of one wheel, the speed of the other wheel increases (in the opposite direction) by the same amount as the decrease (Ni + No = constant).

This also explains, if the drive wheels are lifted off the ground and the engine is not running, and the drive shaft is fixed by engaging the gearbox, then the movement of the crown gear / ring gear is stopped, if one of the wheels is manually rotated in this position, this causes the other wheel It rotates in the opposite direction with the same speed (Ni = – No).

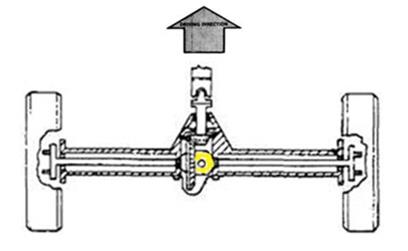

The ring gear transmits the movement and also reduces the transmitted speed and increases the torque, in addition to converting the longitudinal movement into a transverse movement (the front-engine, Rear-wheel-drive layout- FR gearbox). In rear-wheel drive cars, the differential gearbox is connected to the half-shafts passing through the rear axle blank and which are connected to the rear drive wheels.

|

| Front-wheel drive car, rear-wheel drive |

Front-engine, Front-wheel-drive layout- FF vehicles have a pinion at the end of the gearbox main shaft. The differential gears are inside the same blank with the gearbox. And out of them separate shafts of management for each wheel.

|

| Front drive car, front wheel drive |

Position of the differential on the car:

| rear wheel drive | front payment | four wheel drive |

|  |  |

| rear differential | front differential | 3 differentials (front – middle – rear) |

If you turn/turn to the right, the right wheel will turn slower and travel less distance than the left wheel. The central diff works the same way as the front and rear gearbox, but between the front and rear axle instead of the left and right wheel. The distances traveled by the front and rear wheels in the coil are not the same and therefore a center differential is needed. The first division between the front axle and the rear axle is done by the center differential, then each differential axle divides the power given to it between the right and left wheel.

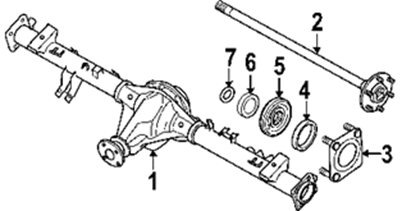

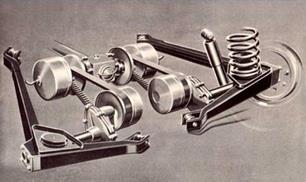

Rear axle parts:

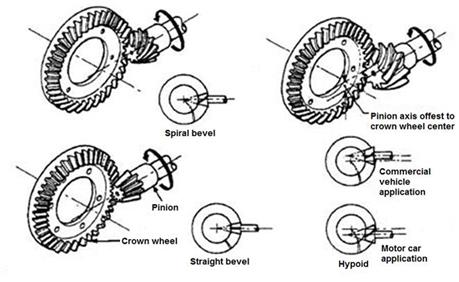

Types of gears used in the differential box Types of bevel gear:

Different types are used in the combination of the bevel pinion gear with the crown gear wheel (straight, spiral, hypoid). The hypoid gear is commonly used in differential gears because the bevel gear is The pinion gear allows the shaft (in automobiles) to be attached below the center of the crown gear, or at the top of the center of the crown (for commercial vehicles). This will reduce the height of the propeller shaft tunnel, which forms an elevation in the floor of the vehicle. Or in the case of commercial vehicles, it reduces the angle of inclination of the shaft and thus the working angle of the universal joint.But this type of gear needs stronger bearings, and it needs lubrication of a special type to resist wear in the teeth of the gears, and it has low efficiency.

|  |

| |

| Pinion gear and crown gear for rear wheel drive cars | Ring gear and differential gearbox for front wheel drive cars |

|

| A pair of hypoid gears connects the drive shaft to the differential. |

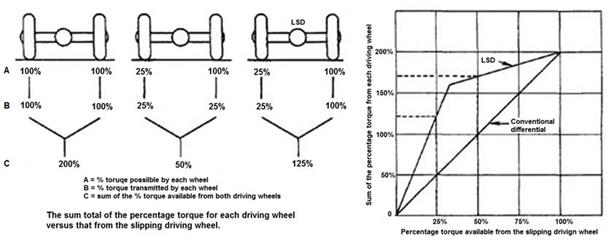

Loss of traction

One of the undesirable side effects of a conventional differential “open” gearbox is that it may reduce traction from the ideal condition. The traction force required to drive the car at any given torque in different cases such as: the weight of the car, the amount of traction and friction available, the road inclination, the inertia force of the car (during acceleration and braking, turning)…. etc.

In the event that the torque acting on one of the driving wheels exceeds the traction limit between the tire and the road, the wheel will spin, and thus the differential provides torque to the other wheels limited and equal to the sliding torque of the sliding wheel. Limited net traction may not be sufficient to propel the vehicle. An example would be in the case of rear-wheel drive wheels, one wheel traveling on asphalt and the other wheel on slippery ground (ice), and since the crankshaft box splits torque equally between the wheels on each side, the torque acting on the side under the asphalt will be limited to that limit.

As it is not possible to transfer more torque to a driving wheel than to the other wheel as a result of the balance action of the differential gears, in the event that one of the wheels passes on a slippery ground so that it rotates without forward movement, there will be no thrust from the other wheel. This is overcome by using a differential lock. By means of a dog clutching on the sun pinion, it closes it with the differential cage. Alternatively, limited-slip differential (LSD) can be used by means of a solid or viscous friction between the sun gear and the gear carrier that will affect some of the torque on the wheel that has it and grip the road.

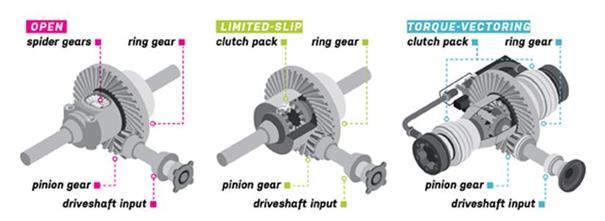

Differential gear types:

- Conventional differential gearbox (also called open differential gearbox) always acts with equal torque for both

Driving wheels. In the case of reduced contact between the tire and the road for one of the wheels, the total torque available to each wheel is limited by the torque required to make the wheel with the least contact spin in place. As the car turns in a curve the wheels travel on two different turning radii, the weight of the car is transferred away from the wheel that is traveling on half The inner diameter to the wheel that runs on the outer diameter is the outer diameter, so the inner wheel will lose traction usually in a sharp turn. Especially when accelerating during the bend. Locking differentials and limited slip differentials modify the way torque is distributed to the calf to reduce wheel spin and improve traction in situations where traction is limited.

The wheels can also lose traction if the friction coefficient between the tire and the road is low, such as when there is a layer of snow and ice on it. Also, the open differential delivers only enough torque to cause the wheel with the weakest grip to rotate around itself, in the event that one driving wheel is fixed on a surface with low traction (mud, snow, etc.), the torque delivered is limited by the grip between the tire and the mud.

- limited-slip differential (LSD)

In open differential gears, the torque distribution is limited to 50-50. Even if the wheels rotate at different speeds, the average speed is always the same, equal to the speed of the crown gear.

In a locked differential, the differential is locked together in some cases, such as when the traction available to the two wheels is significantly different. This causes the differential to act as a solid axle, forcing both wheels to spin at the same speed. If the available grip of the wheels is different and the wheels are still spinning at the same speed, the torque distribution is no longer 50-50.

This feature makes the differential lock desirable in difficult terrain, since during half the time one of the wheels is in the air, in the mud or in the water. In the event that one of the wheels is in the air, the open differential will provide zero torque to both wheels, but in the case of a closed differential, it will provide more torque to the wheel on the ground.

A limited-slip differential (LSD) gearbox is a type of differential that allows some difference in the angular velocity of the output shafts, but imposes a mechanical limit on the disparity.

In a car, such a differential is sometimes used in place of the standard differential, as it has some dynamic advantages, at the cost of more complexity.

The main advantage of this type can be demonstrated by considering the standard (open) differential in off-roading or in the case of snow where one of the wheels begins to slip. In that case with a conventional differential, the wheel that is slippery or not connected to the ground will get the majority of the power (in the form of low torque, high rev), since the wheel that is attached to the ground will remain fixed to the ground. The torque transmitted on the open road differential will remain equal at both wheels; In the case of a single tire on a slippery surface, the given torque will easily overcome the existing traction and cause the wheel to spin in place.

Basic principle of operation:

The car’s limited-slip differential gearbox has some basic elements. First, they all have a set of gears, such as those in an open differential gearbox, which allow the output shafts to rotate at different speeds while still having their combined speeds proportional to those of the input shaft.

Secondly, they all have some kind of torque-acting mechanism (inside the differential gearbox) that counteracts the relative motion of the output shafts. In simpler terms, this means that it has some mechanism that resists the speed difference between the output, by creating a resistive torque between the two output columns or the output and the differential blank. There are many mechanisms for generating this resistive torque. This type of differential gets its name from the design of the resistance mechanism.

Examples include viscous LSD and clutch-bases LSD. The amount of limited torque provided varies by design.

- Locking differential:

It is called differential lock, differential lock, diff lock or locker and is different from a standard gearbox. This differential can increase traction compared to a conventional (open) differential by constraining both wheels to the same speed without limiting the available traction or the difference in resistance to which each wheel is subjected.

The closed gearbox is designed to overcome the main problem that limits the operation of a traditional differential by providing locking for both wheels on one axle together as if they were a common axle. This forces both wheels to spin together, with or without tugging on each wheel.

When the wheel is unlocked (open differential), each wheel can rotate at a different speed (such as entering a corner), thus avoiding tire scuffing. An open (unlocked) differential always provides the same torque (rotational force) to both wheels, on this axle. Although the wheels can rotate at different speeds, with the same torque applied to them, even if one wheel is completely stationary, and the other is rotating in place. (Equal torque, different rotational speed).

In contrast, a closed differential forces both the right and left wheels on the same axle to spin at the same speed in almost all conditions, regardless of the differences in contact between them and the road for any of the wheels. Therefore, each wheel can apply as much torque as the contact underneath it will allow, so the torque on each side will be unequal. (unequal torque, equal rotational speed).

A closed gearbox can provide traction advantages over an open gearbox, but only when the contact under the wheels is significantly different.

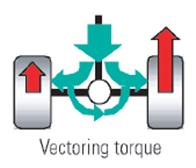

- Torque vectoring:

It is a new technology applied in differential gearboxes for cars. Torque Vectoring technology provides the differential with the ability to increase power at each wheel. This method is now popular in all-wheel drive cars, and some modern front-wheel drive cars as well. With the improvement of automotive technology, more cars are equipped with a torque vectoring differential. This allows the wheels to better grip the road for better performance and handling.

In addition to many other different types of differentials used in some cars, such as: Torsen, which is a type of limited-slip gearbox. The case uses worm gears and a planetary worm gears in place of bevel gears in a conventional differential.

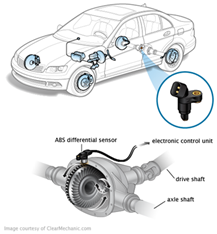

The differential sensor for the wheel locking system ABS Differential Sensor:

Installing a differential sensor on the differential reduces the number of sensors in the car. Not all cars equipped with the wheel lock system have an anti-lock wheel differential sensor. Some cars are equipped with separate sensors for each wheel instead of a single sensor mounted on the differential.

Automobile without differentials:

Although most cars use a differential, there are a few that do not:

Race cars in certain classes, preceded by drag racing in a straight line (mostly on a smooth surface), which does not require the presence of a differential gearbox on the driving axle. It uses a rigid spool between the drive wheels, which is simpler and less likely to break under the influence of high acceleration. Also, racing on dirt or mud tracks allows the use of a rigid coupling unit, because the surface is not tight, and does not pose a problem to the axles and tires. There are also some types of cars for other races that do not use the crankshaft box, which include the following races: mud bogging, tractor pulling, and some other races that use 4×4 cars and do not need a differential gearbox.

Vehicles with one steering wheel, which are not classified as a car, this category includes three-wheeled cars.

Vehicles that use two freewheels. One for each steering wheel. When the car is turning, the engine is still pushing the inner wheel into the corner, but the outer wheel is allowed to turn faster by its free wheel. Thus, when the car enters a curve, the car has only one driving wheel. A freewheel or overrunning clutch is a device in a power transmission system that separates the driven shaft from the drive shaft when the driven shaft is faster than the drive shaft.

Vehicles with continuously variable transmission (CVT), such as the DAF Daffodil. This type of transmission uses two belts and pulleys to provide an unlimited number of gear ratios. The engine drives 2 independent transmissions that drive the two driving wheels. If the car is cornering, the two wheels can be turned at different speeds, by making each of the transmission shafts rotate at a different reduction, thus effectively replacing the differential gearbox. A wheel that is turned slower receives more torque than the accelerating wheel, so the system has a limited slip feature. Also, if one of the belts is cut off, the car can travel with one wheel drive.

Light vehicles with drive wheels close to each other (the distance between the wheels is short), or light vehicles.

– Cars that have a separate motor to drive the wheels. Electric cars can be driven by separate electric motors for each driving wheel, thus eliminating the need for a differential gearbox, but usually with some some types of gears are used to obtain the required wheel torque. The electronic control of the car can control the distribution of power between the motors within a millisecond, in this case acting as a differential gearbox.

Differential Service:

- Check: Differential fluid level / kr

- Supply: Differential fluid

- Change: differential, interlacing, gears

There are no reviews yet. Be the first one to write one.